Installation of Water Leak Sensing Cable for the detection of water

The Water Leak Sensing Cable is used to detect water damage in production, storage, logistics, server room, data center, etc. Wherever basins, water pipes, cooling hoses, etc. can release water, this Water Leak Sensing Cable is used for protection.

Also, installations, machinery and equipment that can cause flooding / water damage, such as heating, cooling and air conditioning (HVAC) or 19 "water cooled server cabinets, should be monitored by installing this water detection cable. Avoid expensive property damage and costly breakdowns by installing this solution.

Used in conjunction with the Water Leak Cable Sensor and Didactum IP-based remote monitoring device (not included), technicians, facility managers and operations managers are notified early if moisture or water leaks. This water detection cable also detects distilled water as well as water containing liquids.

Note from the editors:

For reasons of EMC immunity, our engineers opted for wired sensors. You do not have to worry about radio interference or unsafe radio protocols either. The wired sensors are powered by the Ethernet-based main monitoring system. Therefore, no batteries need to be replaced and no empty batteries packs need to be charged.

Selection of the installation location

This Water Leak Sensing Cable can be installed on the floor, in false floors, in suspended ceilings and along walls. A corresponding number of plastic clips for attaching the cable are included. If you want to install the cable along pipes, heating pipes, cooling hoses, etc., please use suitable cable ties.

Note from the editors:

Mount the Water Leak Sensing Cable as close as possible to the to be monitored object. This ensures that the escape of moisture, water or water containing fluids can be detected as early as possible.

Mounting the water detection cable

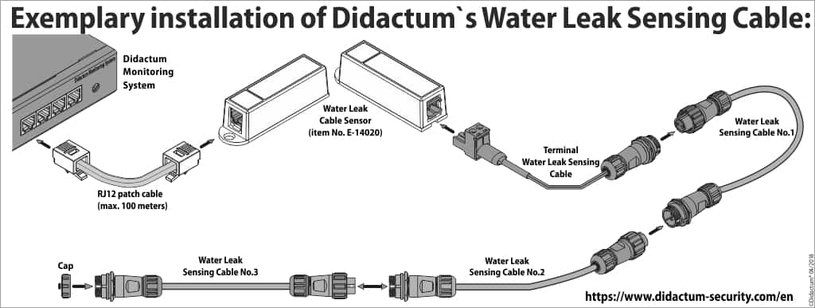

The cable is connected to Water Leak Cable Sensor (not included). To do this, insert the green plug of the connector into the sensor. Check that the green plug is correctly locked to the connection terminal of Water Leak Cable Sensor. Connect the other end of the connection cable (male plug) to the female plug of Water Leak Sensing Cable Important: Each connector is marked with a white dot on the side for reverse polarity protection. When connecting make sure that both points match!

After the plugs have been correctly connected, the union nut of the female connector is screwed onto the male connector until a firm connection is established. Please check afterwards whether the cap is firmly attached to the end of the Water Leak Sensing Cable.

Extend your water detecton cable

The total length of the water alarm cable can be up to 1,000 meters (3280 ft). For this purpose, additional Water Leak Sensing Cables of the same type can connected. Additional cables can be ordered in the online shop in standard lengths of 10, 15, 25 or 50 meters (32, 49, 82, 164 ft).

To extend your existing water leakage detection cable, simply unscrew the end cap and connect another watermelon cable. Of course, the cap must be screwed on at the end of the cable.

Installation of Water Leak Cable Sensor

The Water Leak Cable Sensor (not included) is equipped with a RJ11 / RJ12 connector. A 2 meter RJ11/RJ12 patch cable is included. On request, you can use up to 100 meters (328 ft) long patch cable. Connect the plug of the RJ11/RJ12 patch cable to the sensor. The other plug is simply plugged into a free sensor port of a 50/100/400/500 II/500 II DC / 600/700 series monitoring device.

The predecessor models from manufacturer Didactum are also supported. With the support of Didactum`s innovative auto-identification function, the sensor including the connected water sensing cable is automatically detected by the monitoring unit and listed in the multilingual web interface. Of course, you can give the sensor an individual name ("water detector double bottom", "water alert heating system", etc.).

Alarms and notifications on detection of moisture or water

In the built-in intelligent logic of the IP based remote monitoring system, you can define the normal state ("wet" / "dry") of the water detection cable. Messages and alerts can be sent via syslog messages, via e-mail, via SMS (via GSM / LTE modem or 3rd party e-mail to SMS gateway). Alarm sirens with a flash warning light can be triggered by automatic relay switching. The water damage can be also reported to building monitoring system.

Since all monitoring systems support the SNMP standards v1, v2c and v3 (encrypted), the messages can also be sent in the form of SNMP traps in the event of imminent water damage. The Water Leak Cable Sensor is equipped with an OID (Object Identifier) can be queried by SNMP (Simple Network Management Protocol) commands from building automation software and / or network management systems (NMS),

Note from the editors:

Each Didactum monitoring system can also send so-called disconnect alerts. In case of sabotage or cable break you and your colleagues will be reliable informed.

Function test of the Water Sensing Cable

Use a damp / wet cloth to test the water detection cable. As soon as the cable comes into contact with moisture / leaking water, the alarms and actions stored in the IP based remote monitoring system are triggered.

In the tactical overview of the multilingual webGUI of the monitoring system, the status of the water detection cable is also displayed. Wipe the part of the cable that has come into contact with water with a clean and dry cloth. Didactum`s Water Sensing Cable is ready for use after drying.

Maintenance

This Water Sensing Cable is maintenance free. Every 6-8 months, a bump test should be performed. Furthermore, the installation site should be freed of coarse dirt and dust accumulation. Also check the cable for mechanical damage. If the water detection cable has come into contact with diesel, kerosene, petrol and oil liquids / substances, the cable should be replaced. The same applies to contact with aggressive acids.