Sensor Configuration

Here we show how to configure the sensors that are connected to the remote measuring and monitoring unit.

To configure each sensor first go to the "Main menu“ => “System Tree“ or “Group Tree“ and simply select the sensor element. Here, a window with the sensor properties will pop up.

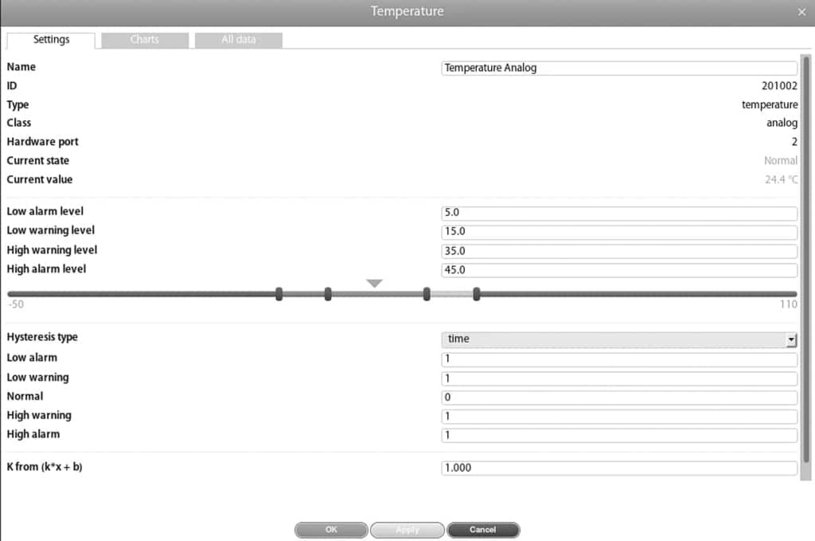

Now you can change the sensor settings and then click "Save" or "Apply" at the bottom of the "Properties" window as shown in the screenshot below.

Important:

To save your sensor settings in the non volatile flash memory of your remote measuring and monitoring unit permanently, please click on the disk icon in the upper right of the webGUI.

All sensors include:

| Name | The sensor name is assigned automatically and can be changed |

| Group | Individual sensors can be summarized under "Group Tree" |

| ID | identification name of the corresponding sensor |

| Type | Here the sensor type is displayed as temperature |

| Class | Display the Sensor class analog, CAN, Switch, Discrete |

| Hardware Port | Shows the port where sensor is connected |

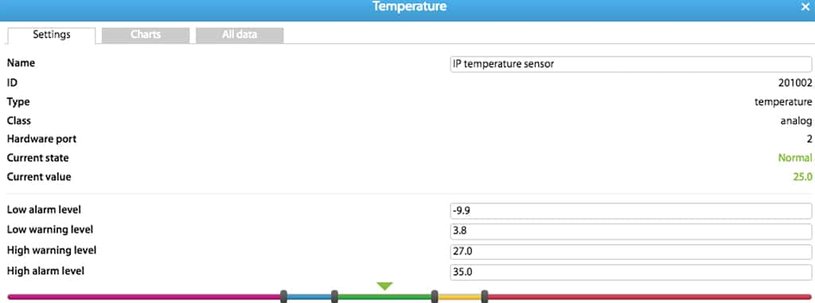

Configurable sensor thresholds and warning values:

All intelligent IP sensors from manufacturer Didactum offer in webGUI individually configurable thresholds and warning values:

Sensor Hysteresis Functions

You can define for Didactum`s intelligent sensors a hysteresis state. With Hysteresis function you can adjust the time or the value the sensor is in a warning, or normal state before the remote monitoring device sends notifications and alerts. This Hysteresis feature was added to firmware 2.7.3 and higher, to eliminate possible false warnings when the thresholds are changing between two sensor states.

Hysteresis can be selected as time or as a value. It can be also be disabled, if you do not need the Hysteresis function. If the hysteresis is set in a time, the sensor will transit to a new state with a delay of the specified number of seconds.

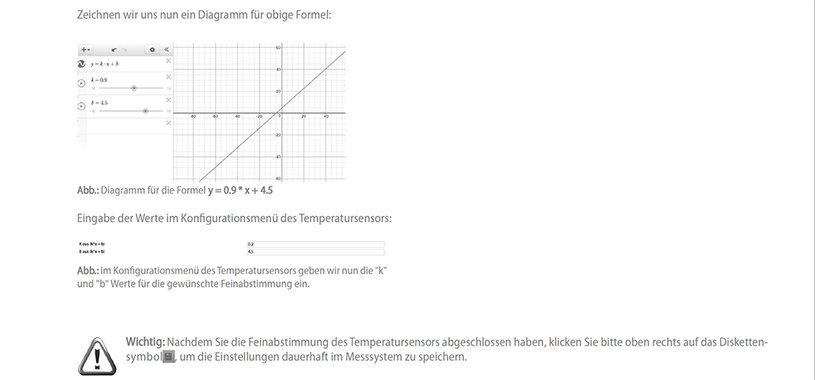

Fine-tuning of Didactum`s intelligent sensors

The IP based, intelligent sensors of the manufacturer Didactum are factory calibrated. In some rare cases, the sensor readings may be too high or too low.

The sensor readings can be adjusted with the help of a simple linear formula. Let's take a look at the following example of the SNMP enabled temperature sensor: