The application possibilities of this water leak detection cable for the detection of moisture and water leakage are manifold. In addition to server room and data center infrastructure, production and logistics areas can also be secured with this field-tested water detection cable from manufacturer Didactum. Typically, the water detection cable is routed to the bottom of 19-inch server enclosure rows and into the raised floor of the server room or data center. The water detection cable can also be easily installed in ceilings and wall coverings. This water leakage detection cable can also be mounted along cooling hoses and (water) pipelines. To attach the detection cable, please use inexpensive cable ties.

Note of the technical editor:

The water detection cable should be mounted as close as possible to the monitored object!

Installation of the Water Leak Detection solution:

- Connect the water leak detection cable to the IP-capable water leak cable sensor . To do this, screw the free cable ends of the leakage cable to the connector of the sensor unit. Then simply connect the plug to the sensor. Afterwards check the correct seat of the plug.

- Lay the water detection cable along the to be monitored lines or objects. When installing the water detection cable in the raised floor of the server room / computer center, care must be taken that the sheathing of the water leak detection cable is not damaged by sharp objects. The water detection cable must not be kinked. A damaged water detection cable must be replaced.

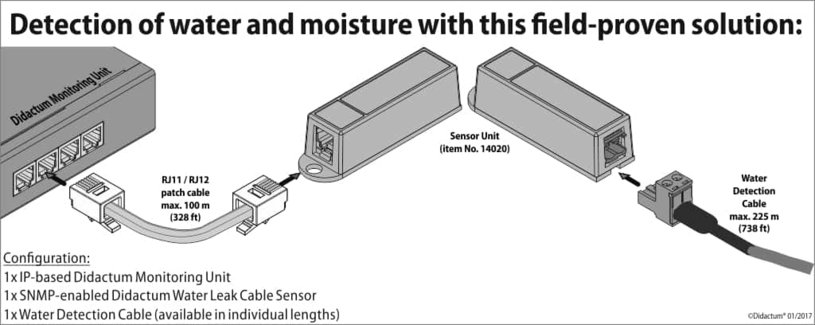

- Connect the sensor to a free sensor port of the IP based monitoring device. To do this, simply use the supplied RJ11 / RJ12 patch cable. If desired, you can use a patch cord up to 100 meters (328 ft) long. The pin assignment of the RJ11 patch cable can be found here in this wiki. Of course you can buy certified sensor cables in our online store. The sensor is automatically detected by the main monitoring unit and displayed in the web interface. Here you can name the water leak detection cable individually (for example, "Leakage cable raised floor" or "Water alarm cable water pipe", etc.).

- Define the required actions, notifications and alarms in the web interface of the monitoring device. The setup of eMail and SMS notifications and alerts is described here.

- Please also use the built-in alarm map of your monitoring system. The alert of the water leak detection cable is flashing on the map. The alarm map supports the rapid localization of water damage within the mission-critical infrastructure.

- Test the water detection cable with a small amount of tap water. After the cable of the water sensor has come in contact with the water, this event is displayed in the multilingual web interface of the monitoring device. At the same time the actions, notifications and alarms stored in logics of the monitoring device are executed. After the test, the water detection cable is dried with a clean and dry cloth. After complete drying, the normal state of the water detection cable is displayed again.

Technical specifications Leak detection cable of the manufacturer (as of 01/2017):

- Cable type: Special 2-wire cable for detection of water and moisture and water-containing liquids

- Detectable liquids: Clean and polluted water. Distilled water. Condensate from air conditioning systems. (Battery) acid, alkali and alcohol and other electrically conductive liquids.

- Weight per meter: 16 grams (without sensor unit)

- Length: Water leak detection cable can be ordered in standard lengths of 6, 10, 25 and 50 meters in the online shop (individual lengths on request).

- Max. Cable length detection cable: Optionally available in special lengths of a maximum of 225 meters (737 ft) (special assembly on request).

- Permitted operating environment: Temperature: -50 ° C to max. +100 ° C

- Reaction time: 15 seconds (typical)

- Assembly: Connection via Water Leak Cable sensor (not in the scope of supply / to be ordered separately)

- Water Leakage Cable reusable: Yes. Reusable by drying*

- Recovery time: Depends on the drying time of the leakage cable.

- HS code 902580400

- Made in: E.U.

Note from the editor:

* Detection cable should be replaced after it has come into contact with diesel, kerosene, petrol and oil liquids / substances.

Technical specifications of Water Leak Cable Sensor (as of 01/2017)

- Sensor suitable for: All Ethernet-based remote monitoring and control devices from manufacturer Didactum

- Auto identification: Yes. Connected sensor is automatically detected by the IP based remote monitoring unit.

- Case dimensions: 60 × 18 × 18 mm

- Weight (net): 60 g

- Input: 2 wire connector for 1x water leak detection cable from Didactum (water leakage cable not included)

- Output: RJ11 / RJ12 socket for patch cable (2 meter patch cable included)

- Operating environment: temperature: min. -10 ° C to max. +80 ° C at min. 5% to max. 95% RH (non-condensing)

- Power consumption: 60mW (typ.)

- Maximum patch cable length: Max. 100 meters (328 ft.)

- HS Code: 902580400

- SNMP OID: Yes. Sensor status (wet / dry) can be queried remotely via SNMP command.

- Reaction time: 15 seconds (typical)

- Made in: E.U.

- Scope of delivery: Mounting material (1x double-sided adhesive tape, 1x screw), 2 meters RJ11 / 12 patch cable, 1x plug